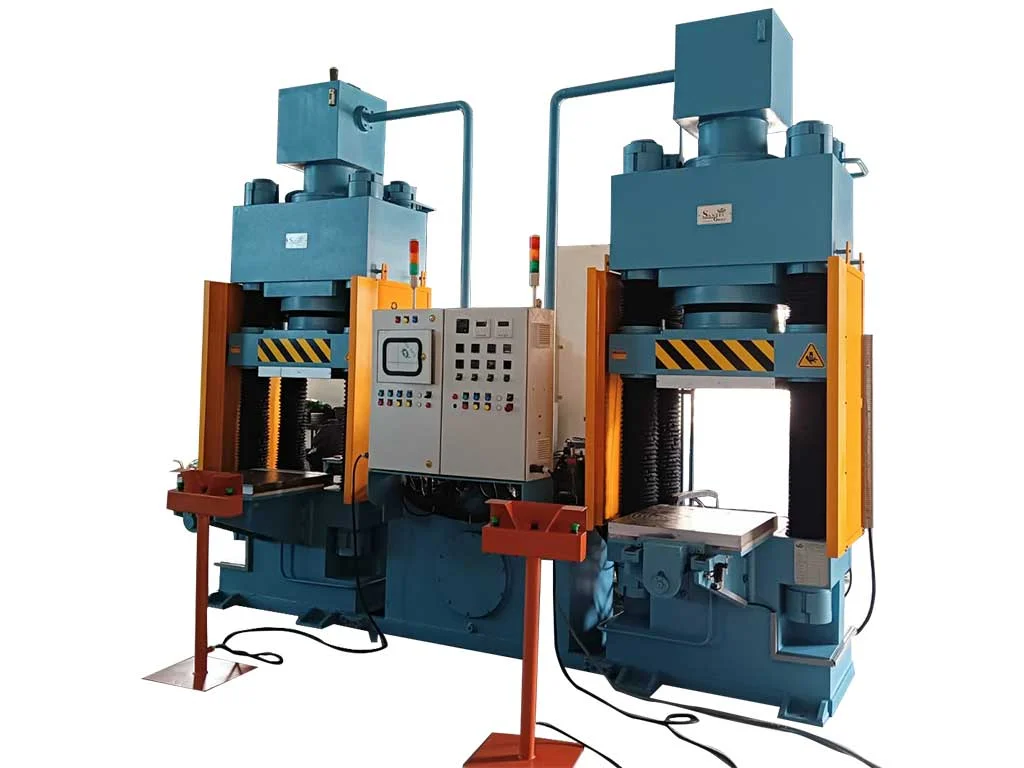

Santec Group offers advanced Compression Molding Presses For Rubber Composites Upstroking Type, engineered to deliver precision, durability, and consistent performance for modern rubber processing industries. These presses are specially designed to meet the demanding requirements of molding rubber composites used in automotive, electrical, construction, and industrial applications. The upstroking design ensures better accessibility, smooth material flow, and uniform pressure distribution, resulting in high-quality molded components with minimal defects.

The Compression Molding Presses For Rubber Composites Upstroking Type by Santec Group are manufactured using robust frames, precision-machined platens, and efficient hydraulic systems to ensure long service life and reliable operation. Advanced temperature control and evenly distributed heating allow accurate curing of rubber composites, enhancing product strength and dimensional stability. These presses support a wide range of mold sizes and capacities, making them suitable for both small-scale and large-scale production environments.

Santec Group focuses on energy-efficient designs, user-friendly controls, and safety-oriented features to improve productivity and reduce operational costs. With customization options available, clients can choose presses tailored to their specific production needs. By choosing Santec Group, manufacturers gain a trusted partner committed to delivering high-performance Compression Molding Presses For Rubber Composites Upstroking Type that ensure efficiency, consistency, and superior molding results.

Comments (0)

Login to post a comment.