Industrial gas and steam turbines rely on robust control systems to manage performance, safety, and efficiency. Among the most significant systems in this space is GE’s Mark IV turbine control system, known for its reliability and digital innovation. A key component within this system is the Data Link Display Board—a module that plays a critical role in communication and system diagnostics.

This article explores the technology, function, and importance of the Data Link Display Board within the context of turbine control systems.

Understanding the GE Mark IV System

Developed in the 1980s, the Mark IV Speedtronic system was GE’s first fully digital control platform for turbine management. It introduced microprocessor-based logic, improved fault diagnostics, and triple modular redundancy (TMR) for enhanced reliability.

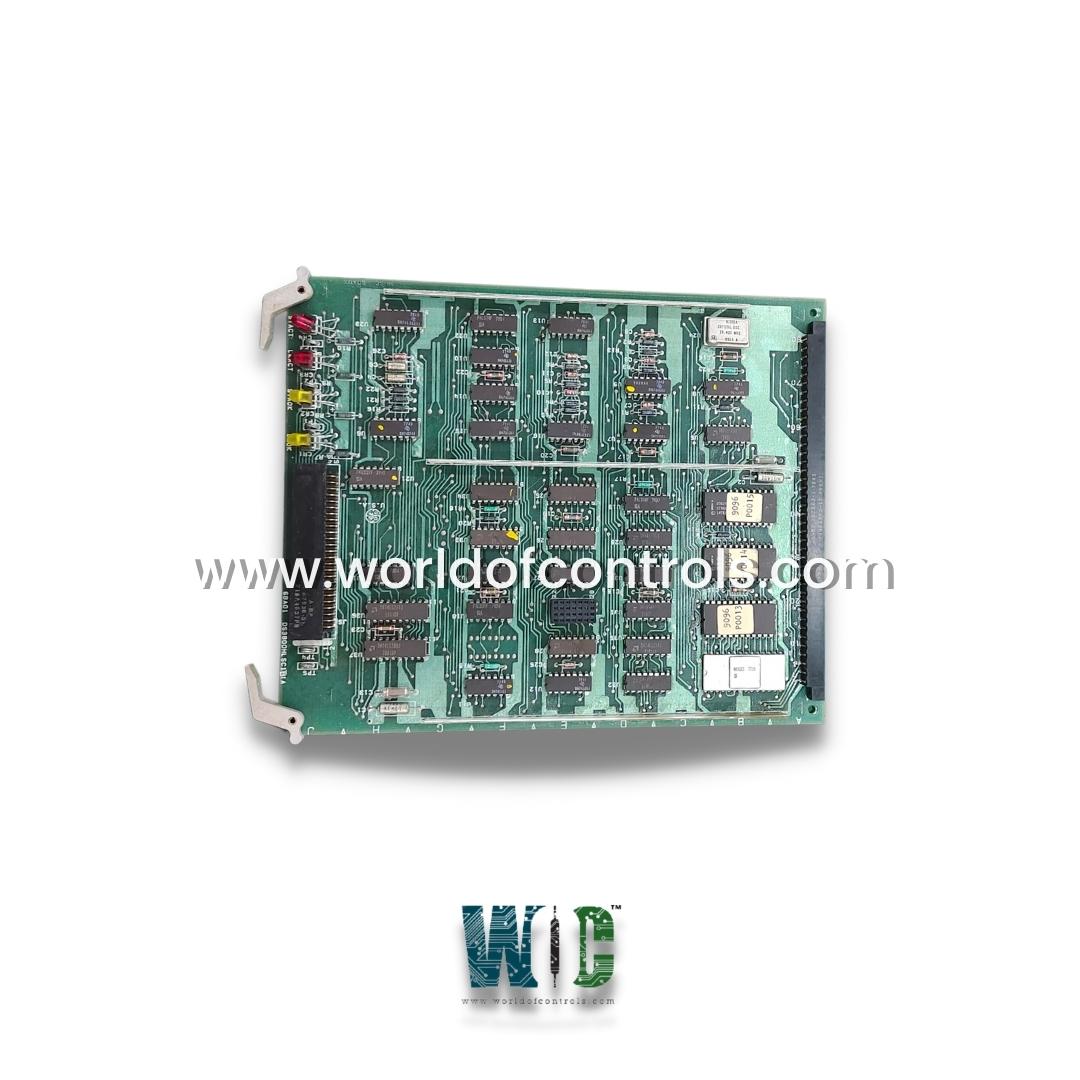

The system is built from a series of interconnected circuit boards, each assigned a specific role—ranging from processing inputs and outputs to memory storage and communication. Among these, the Data Link Display Board provides the crucial function of visually representing system data and enabling internal communication between subsystems.

What Is the Data Link Display Board?

The Data Link Display Board acts as both a communication hub and a diagnostic interface. It facilitates the flow of data between critical components within the control system and offers real-time visual feedback through onboard indicators.

Its primary functions include:

- Data Communication: Transfers operational data between processing units.

- Visual Diagnostics: Displays fault codes, system statuses, and activity logs via LEDs or other indicators.

- Monitoring Support: Helps engineers and technicians quickly identify issues without the need for external diagnostic tools.

This board essentially bridges the gap between digital processes and human-readable information, making it an essential part of daily turbine operation and maintenance.

Key Features and Functions

The Data Link Display Board is engineered to operate under demanding industrial conditions, offering a combination of reliability, clarity, and diagnostic value. Some of its key features include:

- LED indicators for quick fault recognition and system activity tracking

- Standardized connectors for integration with other Mark IV modules

- Built-in signal conditioning to support clean and consistent data transmission

- Error detection mechanisms that enhance system safety and prevent cascading failures

Because the Mark IV system uses a modular architecture, this board can be swapped in or out with minimal disruption, ensuring easy maintenance and system scalability.

Importance in Turbine Control Applications

Turbines operate in fast-paced, high-stakes environments where failures can lead to costly downtime or even hazardous events. The Data Link Display Board helps mitigate these risks by offering immediate insights into system health and communication pathways.

In normal operations, it provides operators with real-time updates, while in fault scenarios, it becomes a frontline diagnostic tool. This visibility is especially important in legacy systems, where operators depend on built-in diagnostics to maintain uptime without access to modern analytics software.

Moreover, the board enhances overall system redundancy and fault isolation, contributing to the Mark IV's continued relevance in industrial settings worldwide.

Maintenance and Replacement Considerations

Although the Mark IV platform is no longer in production, it remains in use across many industries due to its robust design and long operational life. Components like the Data Link Display Board are typically sourced through specialized suppliers of legacy parts, often as refurbished or surplus units.

When maintaining or replacing this board, it's essential to:

- Verify compatibility with the existing Mark IV system

- Inspect LEDs and communication ports for full functionality

- Use proper handling procedures to prevent electrostatic damage

- Test the board in a controlled environment before full deployment

Routine checks of this board can significantly reduce unplanned downtime and improve the lifespan of the overall control system.

Final Thoughts

The Data Link Display Board in GE’s Mark IV system may seem like a small part of a complex turbine control architecture, but its impact is considerable. From ensuring seamless internal communication to enabling efficient diagnostics, it serves as a critical link between machine and operator.

In an age of increasing digitalization, this component stands as a testament to the durability and foresight of early digital control systems—and continues to support power generation systems across the globe.

Comments (0)

Login to post a comment.