In the food processing industry, maintaining a safe and hygienic environment is paramount. One of the critical components that contribute to this goal is the use of high-efficiency vapor tight LEDs for food processing plants. These lighting fixtures not only provide adequate illumination but also ensure compliance with stringent safety standards.

Understanding High-Efficiency Vapor Tight LEDs

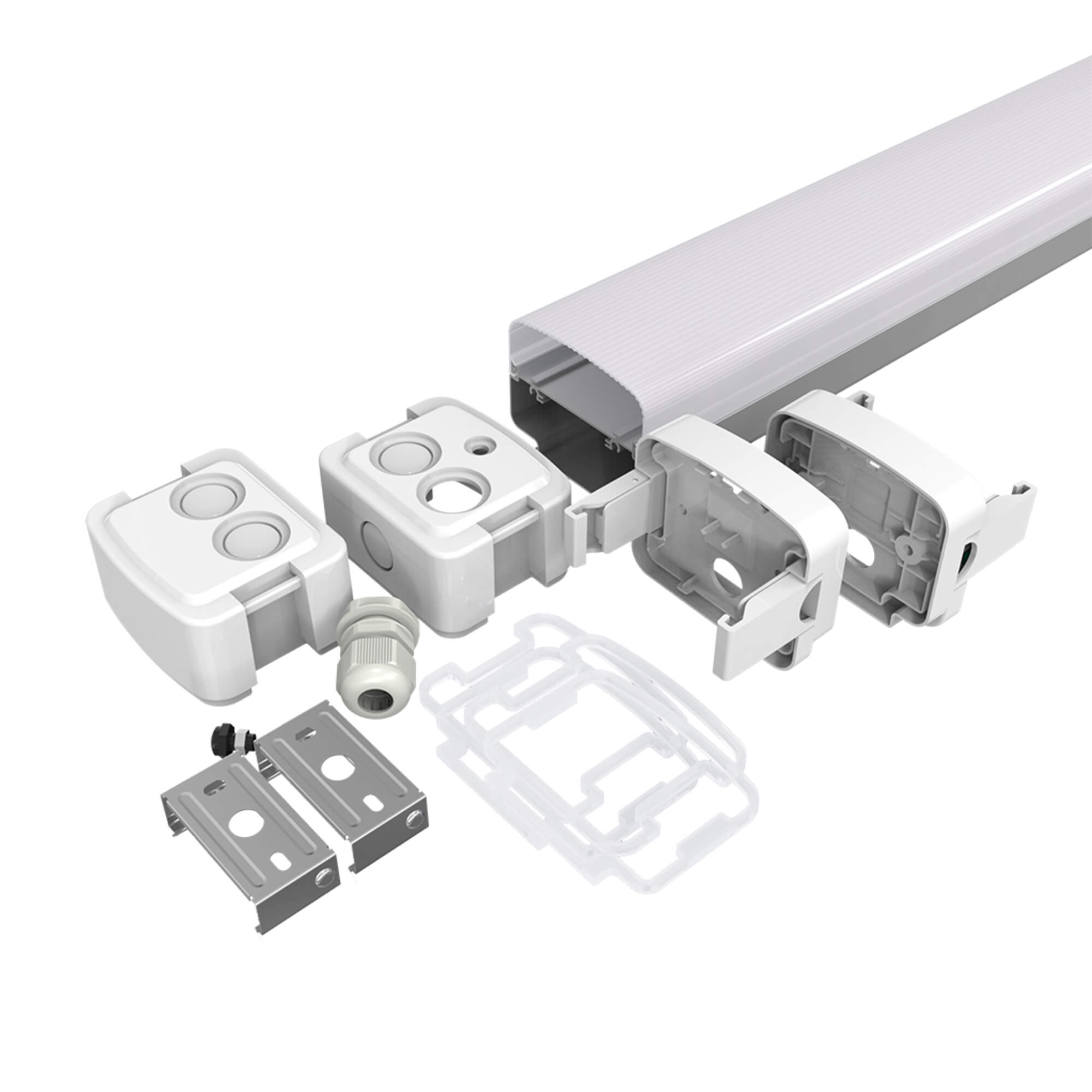

What exactly are high-efficiency vapor tight LEDs? These are specialized lighting solutions designed to withstand harsh conditions, including moisture, dust, and temperature fluctuations. Their robust construction makes them ideal for environments where cleanliness is crucial, such as food processing plants.

- Water-resistant and dust-tight design

- Energy-efficient operation

- Long lifespan, reducing maintenance costs

- High lumen output for optimal visibility

Benefits of Using High-Efficiency Vapor Tight LEDs in Food Processing

Implementing high-efficiency vapor tight LEDs for food processing plants offers numerous advantages:

- Enhanced Food Safety: These fixtures minimize the risk of contamination by preventing the accumulation of dust and moisture.

- Energy Efficiency: With lower energy consumption, these LEDs contribute to reduced operational costs.

- Improved Visibility: Bright, consistent lighting helps workers perform tasks more accurately and safely.

- Durability: Designed to last, these lights reduce the frequency of replacements, ensuring continuous operation.

Compliance with Safety Standards

Food processing plants must adhere to strict safety regulations. The use of high-efficiency vapor tight LEDs aligns with these requirements, as they are often rated for use in hazardous locations. By choosing the right lighting, facilities can ensure they meet local and international safety standards.

Installation and Maintenance Considerations

When considering the installation of high-efficiency vapor tight LEDs for food processing plants, it is essential to evaluate the layout and specific needs of the facility. Proper placement can maximize the benefits of these lighting solutions. Additionally, routine maintenance checks can help sustain their performance and longevity.

For those looking to upgrade their lighting systems, explore options available at  . Investing in quality fixtures is a step towards enhancing food safety and operational efficiency.

. Investing in quality fixtures is a step towards enhancing food safety and operational efficiency.

Conclusion

In conclusion, the role of high-efficiency vapor tight LEDs for food processing plants cannot be overstated. They not only enhance food safety but also contribute to energy savings and compliance with industry regulations. By making informed choices about lighting, food processing facilities can create a safer and more efficient working environment.