Introduction

Despite being core to the developed and emerging economies, laymen don’t hear much about the logistics sector or logistics software development in regular conversations. Therefore, it should surprise you that the logistics industry is going to be over USD 12 trillion by 2027. We don’t usually debate current trends in logistics because the sector has remained aloof from technological advancement.

Notwithstanding this disconnect, the present supply chain management trends suggest logistics is going to be one of the fastest growing sectors globally due to technology penetration and eCommerce ease. eCommerce logistics in the modern world can be considered a big strategic resource for businesses, making them mature and receive competitive advantages or, on the other hand, making them outdated in this rather rapidly evolving industry.

This blog focuses on the top trends in logistics, such as eCommerce integration, warehouse automation, real-time monitoring systems, sustainability, data science, and blockchain, as well as from disposable to durable supply chain movement.

Rise of eCommerce and Its Impact on Logistics

Growth Statistics

- In 2021, eCommerce sales grew to $870.8 billion at the rate of 14.2% in the US despite the covid pandemic and economic downturns.

- eCommerce sales were 19% of the total retail sales in 2019 and could be 22 by the end of 2024 despite supply chain disruptions.

- The growth of USD 20 billion between 2021 and 2028 for the last-mile delivery market in North America alone is phenomenal.

- A National Retail Federation of the US confirms that 75% of Americans are willing to buy online and use a pickup service provided by the store.

- Last year’s report of Invesp suggests that eCommerce logistics gains more ROI—at 25% to 30%—compared to the nook and corner stores.

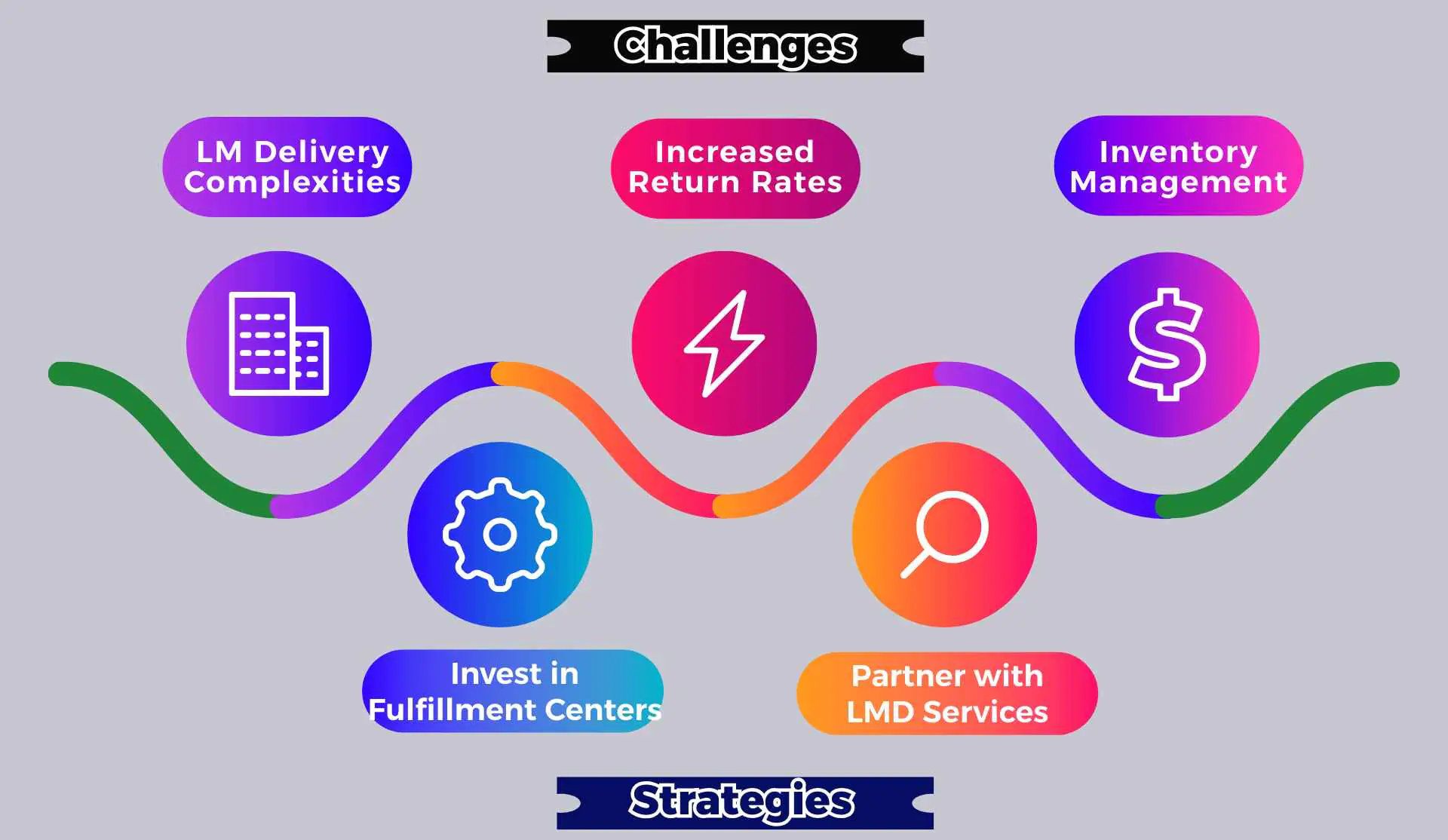

Challenges for Supply Chains

Last-Mile Delivery Complexities:

High traffic density and multiple drop-off points present unique burdens for logistics companies, making it a challenge to provide efficient and affordable last-mile delivery solutions in densely populated areas.

Increased Return Rates:

With the increased impact of eCommerce on logistics comes increased return rates that make reverse logistics a more difficult problem to solve. This trend also brings the need for an effective process to deal with returns, refurbishments, and their integration with inventory.

Inventory Management:

Yet, the often unpredictable nature of demand in eCommerce makes it difficult to provide supply with suitable inventory margins. There is always pressure to ensure that products are available to meet market demands while at the same time keeping the costs of storage as low as possible.

Adapting Strategies

Investment in Fulfillment Centers:

Amazon is also placing its fulfillment centers nearer large metropolitan areas as a move to cut delivery expenses and time, thus enhancing the satisfaction of its customers since their orders will be processed faster.

Partnerships with Last-Mile Delivery Services:

Evaluations with vendors specialized in last-mile logistics are increasingly frequent, using their knowledge and tools to refine delivery in the last stage.

Automation and Robotics in Warehousing

Technological Advancements

Emerging technologies like robotic process automation, AI automation, AR/VR, and blockchain are transforming various aspects of warehousing. The automation in warehousing is expected to reach USD 58 billion from $14 billion within the third decade.

Benefits of Automation

Efficiency Improvements:

By automating the process, there is a notable improvement in the rate of movement of stock in a warehouse through activities such as finding the right item, packing the product, and sorting it. This leads to quicker completion of orders and higher stock across and through stock turns.

Cost Reductions:

Although the cost of implementing warehouse automation at the beginning is high, the recurring cost of recruiting and training employees or paying wages is eliminated in the long run. In addition, the resources for the particular business sector are well utilized. This results in significant reductions in operating costs in the long run.

Error Minimization:

Basically, order processing and inventory management eliminated most human errors through the implementation of automated systems. This increases the general accuracy of calculations, the satisfaction of the customers served, and the dependable performance of organizational operations.

Case Studies

Amazon: Amazon makes great use of Kiva robots in its supply chain at the warehouse for inventory and order picking.

DHL: DHL deployed LocusBots, an intralogistics mobile robot, to increase the rate of picking in its centers.

Ocado: It integrated highly automation in a warehouse system via robotic pickers as well as conveyors.

Real-Time Tracking and Visibility

Importance of Transparency

Utilizing tracking data in the context of logistics creates conditions for timely problem-solving in case of their occurrence. It improves supply chain management since it offers a current database of information necessary for supply chain management, ranging from product delivery to customers.

Technologies Enabling Tracking

GPS, RFID, and IoT sensors are some examples of the main technologies that power real-time tracking logistics. These tools give real-time information on the location and status of inventories within the supply chain, reducing losses.

Customer Expectations

Consumers in the current world want to know what is happening with their shipments. The current status of the orders and the expected delivery times have turned out to be the norm as customers demand better communication with their logistics service providers.

Sustainability in Logistics

Growing Environmental Concerns

Can brand sustainability be explained by consumer trends such as opting for brands that are environmentally friendly? 70% of consumers do so. This change has ensured that logistics firms change with time in a bid to comply with the laws of the land as well as satisfy market needs that support sustainability.

Green Logistics Practices

Eco-Friendly Packaging:

There are signs that firms are switching over to biodegradable and recycled packaging materials. This shift of convenience from non-renewable materials to renewable capability decreases the negative impact on the environment. It serves the purpose of sustainability standards as well as the green conscience of market customers.

Electric Vehicles:

Electric delivery vehicles are the third stream of vehicles in the logistics industry. This transition cuts CO2 emissions, possibly brings down operating expenses in the long run, and responds to global initiatives in the fight against climate change.

Carbon Offsetting:

A large number of those logistics companies are using techniques that go as far as completely offsetting carbon emissions. Such programs spend money on a new renewable power plant to offset carbon release or on tree planting exercises.

Regulatory Pressures:

Governments across the globe are increasingly pumping up the regulatory barriers on emissions for the logistics industry. Businesses are, therefore, changing the way they work by incorporating more environmentally friendly methods and embracing compliance with standards.

Data Analytics and Predictive Modeling

Role of Big Data

Getting insights through big data analytics is helping logistics make better decisions about customers and operations. It can allow companies to identify possibilities to enhance routes, forecast demands, and, in general, find inefficiencies.

Predictive Analytics Applications

The logistics application of predictive analytics for supply chain management also facilitates accurate demand forecasting. Variant planning for consumer demand of materials accordingly. They also improve risk control as they point out supply chain disruption risks before they happen.

Success Stories

UPS: Adopted ORION (On-Road Integrated Optimization and Navigation) system, whereby the firm was able to use data analytics in logistics to determine the most efficient or appropriate route to take so as to mark its fuel expenses to approximately millions while at the same time, the firm was able to minimize its pollutant levels in the atmosphere.

Blockchain Technology in Supply Chain Management

Understanding Blockchain

It is known that the presence of blockchain technology in the logistics chain forms an immutable and clear record of all transactions and product flows. The decentralization of these records improves safety, accountability, credibility, and sustainability in supply chain networks.

Benefits for Logistics

Transparency and Security Enhancements:

As noted earlier, blockchain is capable of keeping an immutable ledger of all the transactions that occur within a supply chain. This transparency helps to minimize fraud, improve the level of confidence in stakeholders, and make the audit of activities in various global interconnected networks easier.

Traceability Improvements:

Blockchain technology in updating the status of the product from the point of origination to the destination. This increased visibility further guarantees that the product coming into the market is genuine, makes recalls manageable, and reveals issues in the supply chain.

Real-world Applications

Some organizations have started experimenting with using the blockchain in supply chain management. For instance, Walmart uses the IBM Food Trust blockchain to track food products, increase food safety, and minimize waste due to better tracking.

Related Article: What Are The Benefits Of Investing In Logistics Application Development?

The Shift Toward Resilience and Risk Management

Impact of Global Events

As recent disruptions all over the world have shown, including the COVID-19 pandemic, the conventional linear supply chain models are weak points. They illustrate the paramount importance of developing and implementing robust and flexible logistics management software.

Strategies for Building Resilience

Diversification of Suppliers:

Many firms are also diversifying their sources of supply in order to avoid relying on limited suppliers only. This strategy minimizes risks arising from regional disturbances, political instability, or issues affecting the supplier, hence maintaining operations.

Investment in Technology:

Companies are using smart technologies to improve the understanding and dynamism of supply networks. This includes such functions as real-time tracking logistics, predictive analysis, and cloud technologies for improved coordination and decision-making.

Building Inventory Buffers:

Most firms are reevaluating their lean inventory systems, which include just-in-time systems. Pursuing security stocks within a supply chain plan is a critical aspect of keeping strategic stocks of key components or products, which allows a business to keep operating under adverse events.

Future Outlook

The Logistics management software of the future will probably entail the hard work of developing strategic and agile concepts of supply networks. As a result of digitalization, organizations will implement solutions in order to optimize their strategies for addressing volatile markets and other unpredictable circumstances.

Source: https://www.sigmasolve.com/top-current-trends-in-logistics-and-supply-chain-management/