The Basalt Fiber Market is on a promising growth trajectory, yet it faces distinct challenges that could slow its commercial expansion. These hurdles, if unaddressed, may limit the material’s penetration into key industries despite its performance, durability, and environmental advantages.

One of the primary growth challenges is achieving price competitiveness with conventional composites like glass fiber. While basalt fiber’s mechanical and thermal properties are superior, its production process remains more expensive due to specialized equipment, high-temperature melting requirements, and energy costs, making it less appealing to cost-sensitive markets.

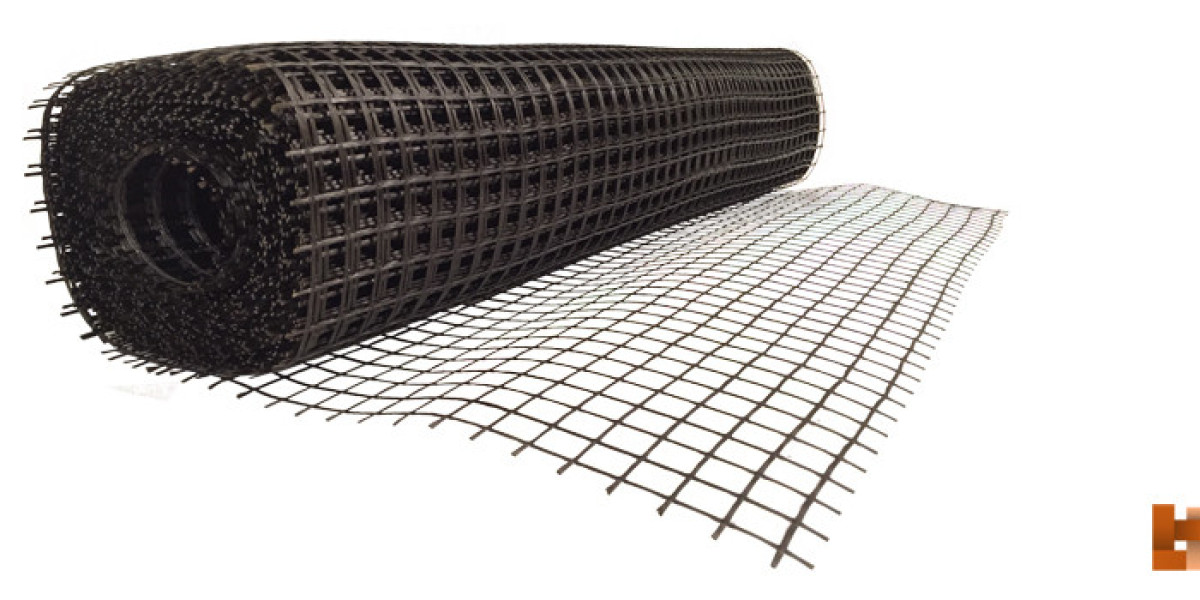

Scaling production without compromising quality is another significant challenge. As demand rises in construction, automotive, aerospace, and renewable energy sectors, maintaining consistent fiber quality while ramping up output requires advanced manufacturing technology and stringent quality control measures.

Market education remains critical. Many industry stakeholders are still unaware of basalt fiber’s benefits or uncertain about its long-term performance in large-scale applications. This lack of awareness slows adoption and reinforces reliance on traditional materials.

Global standardization is also a growth barrier. Without widely recognized testing protocols and performance benchmarks, potential buyers may hesitate to invest in basalt fiber solutions, especially for mission-critical applications in defense, transportation, or infrastructure.

Supply chain resilience poses yet another challenge. Dependence on specific volcanic rock sources, combined with logistical and geopolitical risks, can disrupt material availability and project timelines.

To overcome these growth challenges, market leaders must focus on R&D-driven cost reduction, invest in automated manufacturing, promote global standards, and create targeted awareness campaigns. Strategic partnerships with end-user industries can accelerate adoption and expand basalt fiber’s commercial footprint.