Aerospace elastomeric isolators serve as the first line of defense against vibration and shock in aircraft systems. From avionics to engines, these isolators ensure that critical components remain operational under harsh in-flight conditions. The market’s growth reflects the aerospace industry’s focus on safety, comfort, and efficiency.

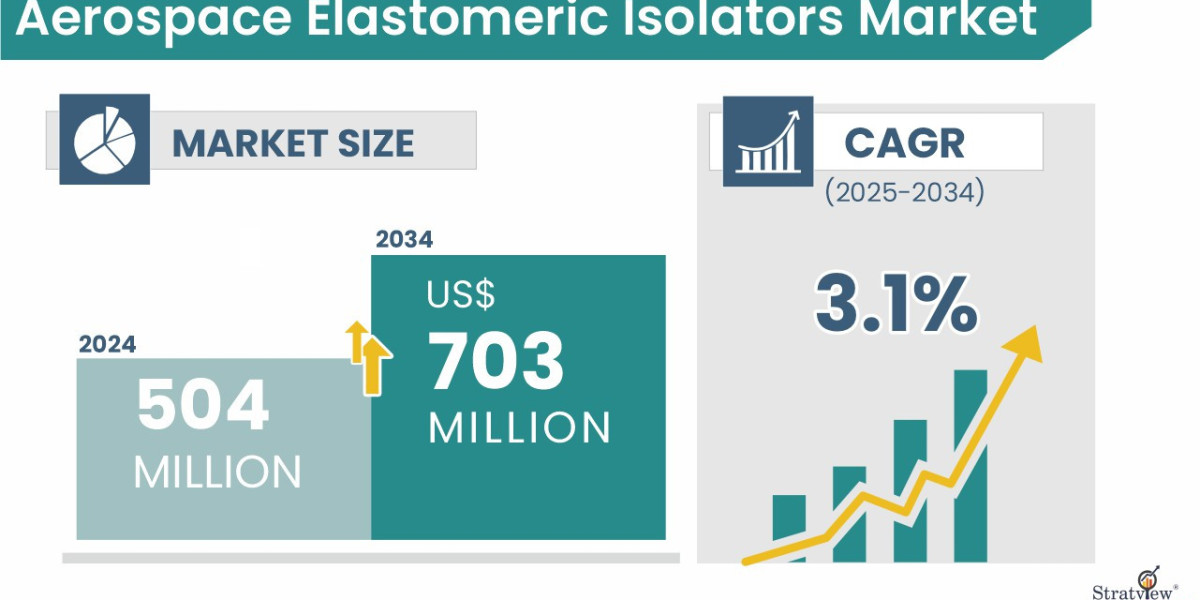

According to Stratview Research, the aerospace elastomeric isolators market was estimated at USD 504 million in 2024 and is likely to grow at a CAGR of 3.1% during 2025-2034 to reach USD 703 million in 2034.

Request a sample report to preview our in-depth analysis.

https://stratviewresearch.com/Request-Sample/4084/aerospace-elastomeric-isolators-market.html#form

Drivers

- Passenger Comfort: Demand for reduced cabin noise and smoother flight experiences.

- Equipment Longevity: Minimizing wear and tear on avionics and control systems.

- Military Modernization: Advanced defense aircraft require high-performance vibration isolation.

- OEM Collaborations: Closer partnerships between isolator manufacturers and aircraft builders.

Challenges

- Harsh Operating Environments: Exposure to oils, fuels, and temperature extremes.

- Customization Demands: Need for application-specific designs increases lead times.

- Regulatory Compliance: FAA and EASA approval processes can delay market entry.

Trends

- Hybrid Isolation Systems: Combining elastomeric and metallic components for optimal performance.

- Additive Manufacturing: 3D printing of mold tools for faster prototyping.

- Space-Ready Designs: Isolators designed for spacecraft payload vibration control.

Conclusion

The aerospace elastomeric isolators market is moving toward highly customized, high-performance solutions. Collaboration, rapid prototyping, and material innovation will be key growth levers.